Industriell kodläsare och maskinvision

2022-12-30 14:32

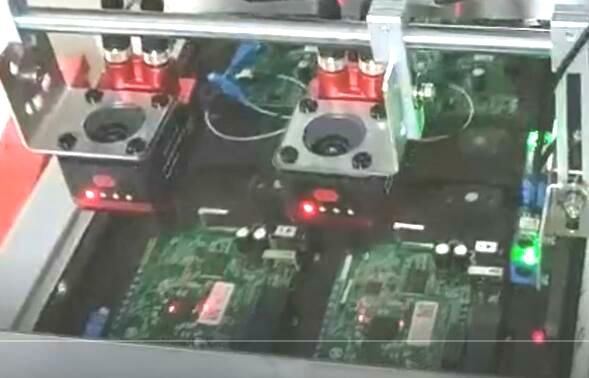

With the advent of Industry 4.0, a new term -- machine vision has gradually emerged in all walks of life. But many people do not know what machine vision or industrial barcode reader is. Machine vision is to replace human eyes with machines for measurement and judgment. Machine vision system refers to converting the captured object into image signal through machine vision products (i.e., image capture devices, including CMOS and CCD) and transmitting it to a dedicated image processing system, and converting it into digital signal according to pixel distribution, brightness, color and other information; The image system performs various operations on these signals to extract the characteristics of the target, then controls the equipment action on the site according to the discrimination results.

(Click on to check infoscan recommanded model FV2X0 / FV105 / FV104 / FV6X / FV3X / HS3050 / HS3260 / HS3155)

Machine vision system includes:

1.illumination source

2.camera lens

3.industrial barcode scanner

4.image acquisition/processing card

5.image processing system

6.other peripheral equipment

As per the industrial barcode reader, as a product of the Internet of Things, it scans and identifies the coded information on the object surface through the built-in scanner of the machine, helping to achieve barcode traceability in the industrial production system. It is a relatively basic instrument in the field of industrial machine vision and an indispensable part of the entire industrial intelligent production process.

With the support of built-in powerful algorithms and visual hardware equipment, the fixed industrial code reader can read the barcode faster, with higher accuracy and farther distance. It is a powerful assistant in the production work of some large and medium-sized manufacturing enterprises.

(Click on to check infoscan recommanded model FV2X0 / FV105 / FV104 / FV6X / FV3X / HS3050 / HS3260 / HS3155)

Industrial barcode reader, also known as industrial camera, has high image stability, high transmission capability and high anti-interference capability. Nowadays, most industrial barcode readers on the market are based on CCD or CMOS chip.

At present, CMOS image sensors have been widely used in high resolution and high-speed applications due to their good integration, low power consumption, high-speed transmission and wide dynamic range.

Få det senaste priset? Vi svarar så snart som möjligt (inom 12 timmar)